The Big Grain Mill Test

The right grain mill for every need

Grain Mill tests of many mills in practice

On this website I have compiled and presented almost all electric grain mills with stone grinders available in Germany so that you can make an informed purchase decision. As far as I have tested the mills myself in my 20-year career as a specialist mill dealer, I provide information about the essential features of grain mills for for home use and try to give you an overview. In my "Small Mill Guide" I have summarised all the essentials. After looking through my mill pages, you can be sure that you know all the relevant models and can make a conscious choice without telling you which mill is the best for you.

45 videos with the Mockmill 100 in test even with dried rose petals, cinnamon sticks, Himalayan salt

45 videos with the Mockmill 100 in test even with dried rose petals, cinnamon sticks, Himalayan salt

Test Winner - Recommendations at a glance

Every mill has its strengths and special features. Ultimately, the fineness and quality of the ground wholemeal flour are decisive, which is particularly noticeable in baking. Thus, every manufacturer favours its grinding stones. The most common are grinders made of corundum ceramic (Co-Ce) next to basalt magnesite (Ba-Ma) at Elsaesser, as well as WIDU mills and natural stone granite (Na-Gra) at Salzburger

Co-Ce

400W·100g

249,- €

Co-Ce

360W·100g

459,- €

Na-Gra

360W·100g

ab 748,- €

Co-Ce

600W·200g

349,- €

Co-Ce

250W·100g

299,- €

Co-Ce

360W·125g

449,- €

Co-Ce

360W·125g

299,- €

Co-Ce

360W·100g

ab 719,- €

Ba-Ma

600W·300g

ab 558,- €

Ba-Ma

500W·250g

998,- €

Basic Questions about the Purchase of a Grain Mill

Table of contents:

Reasons for having your own grain mill at home

Clarification of the need for a grain mill

- Grain Mill with manual drive

- Electric grain mill

- Grain Mill with stone grinder

- Grain Mill with steel grinding mechanism

- Alternative flaker / grain crusher

Features of grain mills for home use

- Grinding stone types and shapes

- Grinder with corundum ceramic discs

- Grinder with natural stone granite discs

- Grinder with basalt magnesite cone

- Grinding stone surfaces

- Adjustment systems

- Adjustment by turning the hopper

- Adjustment by lever

- Adjustment by turning the adjustment knob or wheel

- Adjusting the grinding stones

- Engine and power

- Loudness

- Fineness of the ground wholemeal flour

- Which grains can be milled?

Reasons for having your own grain mill at home

Why have your own grain mill?

But there is ready-made wholemeal flour in organic quality. Yes, but ...

-

It has to be fresh if it is to be wholesome.

The most important reason is freshness. Food ingredients are exposed to a devaluing oxidation process as soon as they are broken down or crushed. Therefore, cereals should be consumed or further processed as soon as possible after milling. On an apple or banana, oxidation becomes clearly visible a short time after peeling. The surface turns an unappetising brown. Unfortunately, this is not visible with wholemeal flour. Not with white flour anyway, because it only contains the white endosperm without the outer layers and germ. Even if wholemeal flour does not change colour after milling, it becomes increasingly worthless and rancid over the course of hours and days because of the oils it contains.

-

Cereals and fruits in their entirety according to the wholefood diet

So you want to grind cereals and grains yourself so that you can process them fresh and in their entirety (e.g. bake bread) and consume them, entirely in the sense of a healthy, wholesome diet as also propagated by the nutritional doctrine of the "wholefood diet".

-

DIY - Do it yourself

Or you may simply enjoy preparing cereal and grain dishes in an archaic way, from the unadulterated raw product to the finished meal.

-

Enjoy full aroma

And you want to enjoy the full aroma of freshly milled grains.

Only if you are really interested in this is it worth buying an electric grinder. Unlike a juicer or blender, which gives you a finished meal or drink after grinding, the work really starts after grinding until you can enjoy the ground food as a finished meal.

The baker says: "Only in homemade bread do you know what's in it."

The baker says: "Only in homemade bread do you know what's in it."

Children have great fun baking.

Children have great fun baking.

Clarification of the need for a grain mill

Manual grain mills

If you only need fresh meal for a fresh grain porridge and wholemeal flour in small quantities, a small hand grain mill is perfectly adequate. With large hand mills (with grinding stones!) you can certainly grind grain into fine wholemeal flour, but with a relatively high expenditure of time and energy. Only those with conviction grind the flour for their wholemeal bread or wholemeal cake by hand.

Grinding by hand has one relevant advantage: the ground material is not heated as much as with electric grinding. This has a positive effect on the preservation of the ingredients (amino acids, vitamins, oils, proteins, etc.), which are devalued or destroyed at higher temperatures. It is also noticeable when processing doughs for bread and cakes. The doughs become looser and accordingly rise better during baking.

Electric grain mills

Electric grain mills are recommended by themselves if you want to bake rolls, bread, cakes and pies with freshly ground wholemeal flour: Always fresh wholemeal flour at the touch of a button without time-consuming and laborious manual work. In just a few minutes, the grain is ground for home use. In addition, with most electric mills you can also grind hard and larger grains such as maize, chickpeas, buckwheat, etc., often also coffee and other grain-like spices.

Advantage of electric grain mills

Grinding is simply faster and effortless. Even hard grains can usually be processed.

Powerful electric grain mill for large requirements, here the Fidibus XL

Powerful electric grain mill for large requirements, here the Fidibus XL

Grain Mills with stone grinding mechanism

Here everything revolves around mills with stone grinders, as these are best suited for grinding grain. The grains are ground between the grinding stones and the endosperm is separated from the husk. The hard husk is squashed, compressed and crushed by the friction. The finer, the more velvety the wholemeal flour feels. The compressed husk absorbs the water better, making doughs more homogeneous and fluffier.

Advantage of stone grinding mills

Better and finer flour from the whole grain for baking and cooking.

Old stone mill at Katzbrui Watermill Mill Museum

Old stone mill at Katzbrui Watermill Mill Museum

Grain Mills with steel grinding mechanism

I have left out mills and milling attachments with steel milling mechanisms because they generally do not grind as finely as stone mills. Experience has shown that the baking properties of flour from steel mills are not as good as from stone mills. While grinding stones squash, compress and crush the grain, the grains in steel mills are more chopped and cut. You can also see this in the jagged shape of the steel grinding cones. The flour, even if it is relatively finely ground, feels more gritty than from stone mills.

It depends on the need

But for coarse grist, e.g. for fresh grain porridge, they are perfectly adequate. If necessary, you can also use a hand-operated or electric coffee grinder. The small, space-saving Jupiter universal mill should not go unmentioned here. With the various attachments, you can actually grind everything you need in the wholefood kitchen. For Jupiter and other food processors, in addition to the grating attachments and a steel grinding attachment, there is also a Schnitzer stone mill for Jupiter and other food processors

Advantages of steel grinders

They are good for all kinds of small grains (also cereals) and grain-like spices, also millet, mustard and oil seeds in small quantities (tablespoonfuls). They are easy to disassemble and clean.

Steel cone grinders not optimal for grain, but versatile and easy to clean

Steel cone grinders not optimal for grain, but versatile and easy to clean

Image: Muehlenprofi

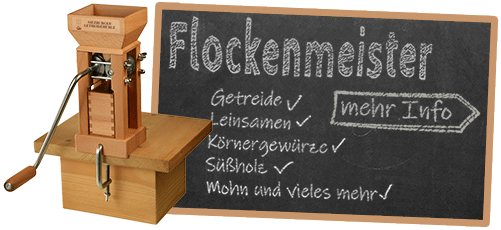

Alternative flaker / flake crusher / grain crusher

A flaker is a real alternative to a grain mill when only the fresh preparation of an organic muesli or fresh grain porridge is required. For quick muesli as opposed to fresh grain porridge, where the grain meal is soaked for several hours, a flaker is even better because the hard husk is compressed or crushed better than with coarse crushing with a grain mill. The hard hulls are virtually pre-chewed and thus better digestible.

The difference between a grain flaker or a grain crusher and a grain mill is explained with pictures on the page "Flaker or mill".

Advantage of a flaker

Better suited for quick organic muesli without prior soaking. Fast fresh cereal flakes with few turns.

Features of grain mills for home use

Grinding stone types and shapes

There are three types of stone for the grinding stones here:

- Natural stone granite

- Corundum ceramic

- Basalt magnesite

There are also two grindstone shapes:

- Discs

- Cones or cone discs

Millstone in front of Katzbrui watermill

Millstone in front of Katzbrui watermill

Grinder with grinding stone discs made of corundum ceramic

Most manufacturers use disc grinders with grinding stones made of corundum ceramic because of the extreme hardness, porous surface and durability. The corundum in the grinding stones is technically produced electrocorundum (aluminium oxide Al2O3) with a ceramic binder. During firing (over 2000°C), small pores are created which make the stones "sharp". The abrasion of these stones is so low that it does not really matter. No wonder that most manufacturers use this type of stone.

Unfortunately, I have not yet found out why all corundum-ceramic grinders in electric mills are only available in disc form (as of 2021). I think it is due to the design of the mill body. Conical millstones require more space and would thus make the mill body seem a bit chunkier. Interestingly, a grinding mechanism made of corundum ceramic in conical shape is so far only available in the KoMo hand mill and in the Mockmill grinding attachment for KitchenAid.

Corundum ceramic grinding stone with porous surface in the Mockmill LINO 100

Corundum ceramic grinding stone with porous surface in the Mockmill LINO 100

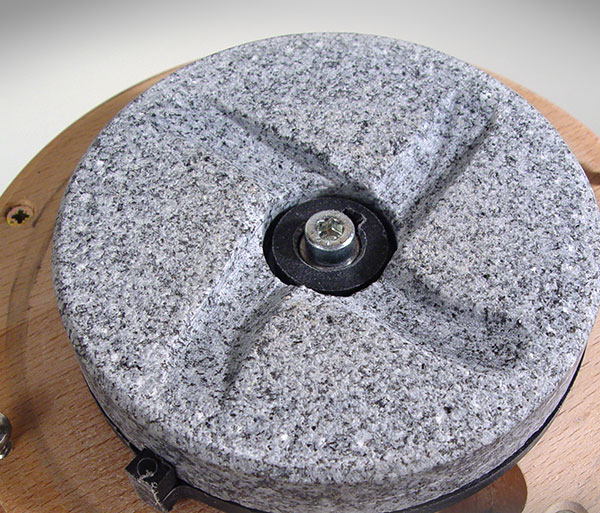

Grinder with grinding stone discs made of natural stone granite

Other manufacturers look suspiciously at this stone from Salzburg, which fetches heavenly mill prices. What often remains unmentioned, however, is that the production of such stones (granite) is much more costly than that of artificial stones (corundum ceramic or basalt-magnesite mixture). The granite grindstone is also very hard and "self-sharpening" due to its different hard components. Re-sharpening is only necessary after many years and countless grinding processes. Due to the smoother and finer-pored surface, the grain is crushed (ground) more than it is ground or chopped. The flour feels very velvety. Salzburger himself reports interesting customer information about energetic behaviour and spectral colours as well as praise from kinesiologists and alternative circles.

Granite natural stone in the Salzburger MT5

Granite natural stone in the Salzburger MT5

Grinding mechanism with cone-shaped grinding stones made of basalt magnesite

There are also artificial stones, basalt bonded with magnesite, but not fired. Such stones also consist of pure natural materials without the addition of questionable additives. The abrasion is rather beneficial to health, as it contains the much sought-after magnesium. This type of artificial stone is mainly found in hand mills, but also in the electric mills from Elsaesser and Widu-Mühlenbau. Although the stones are not as hard as the corundum ceramic stones and natural stones (granite), they also deliver the best grinding results, which is probably also due to the conical shape, which offers more grinding surface for the same diameter. More grinding surface means that the grain is ground longer and can therefore be ground finer than with disc grinders of the same diameter. The Alsatian F100 can grind hard grains such as maize finely without any problems. The same applies to Widu mills, which can also grind soft and oily seeds such as sunflower seeds, sesame seeds, chopped nuts and even coconut flakes.

Conical grinding mechanism made of basalt magnesite at the Schnitzer Hand Mill Country

Conical grinding mechanism made of basalt magnesite at the Schnitzer Hand Mill Country

Grinding stone surfaces

All grinding stones have a profile. The design or shaping is a science in itself. The profiles are also different for each manufacturer, so that you can't really say which one is the best or produces the finest grinding result.

Pair of millstones in front of the old mill in Tutting / Kirchham

Pair of millstones in front of the old mill in Tutting / Kirchham

Adjustment systems for household grain mills

There are three adjustment systems for the flour fineness

Adjustment by turning the hopper

It is the most commonly used adjustment technique. By turning the hopper, the distance from the lower rotating to the upper stationary millstone is regulated by means of a thread. Like turning a screw, the distance between the grinding stones changes. A larger distance produces a coarser grinding result, a smaller distance a finer one. Since the threads are not limited, the distance between the stones can be set so close that they rub against each other and finally block when they come to a stop. Likewise, in the other direction, the stones can be turned up so far that the grains are ejected almost unground, provided the thread reaches that far. With this "unlimited" adjustment system, there is never any need for readjustment, because the adjustment is practically always made automatically by turning the hopper. Another advantage of this system is that it is equally easy to operate for left- and right-handers. And if the grinding stones should ever become smeared, you only have to turn the hopper all the way open and lift it off to be able to clean them.

With this simple, effective technique, however, there is also something to consider: The handling takes some getting used to. One must not forget to tighten the locking screw, otherwise it can easily happen that the upper standing millstone, which is firmly connected to the hopper in the mills with locking screw, rotates and then the millstones are blocked at one stroke. It then takes a great deal of force to release them from each other again.

Ingenious solution for KoMo- und Schnitzer mills

There is a solution to the problem of blocking: the millstone is separate from the hopper and, in addition, the hopper is held in position with a fluted swivel. The ribbing prevents the hopper from turning and thus eliminates the need for the locking screw in the KoMo and Schnitzer mills.

Fluting on the slewing ring and millstone holder at KoMo and Schnitzer, similar for Mockmill

Examples: Adjust by turning the hopper. The knobs on the side are the locking screws: Waldner Silence, Elsaesser F100, Salzburger MT12

Examples: Adjust by turning the hopper. The knobs on the side are the locking screws: Waldner Silence, Elsaesser F100, Salzburger MT12

Examples: Hopper adjustment without locking screw: KoMo, Schnitzer and Mockmill

Examples: Hopper adjustment without locking screw: KoMo, Schnitzer and Mockmill

Adjustment by lever

It is a speciality of hawos, a convenient, easily reproducible adjustment of the flour fineness that has been perfected. Here, too, the distance between the grinding stones is regulated by turning a thread, but not on the hopper, but on the adjustment lever on the side to the right or front. In the hawos mills (Billy, Queen, Novum and Oktagon), the motor and grinding unit or grinding chamber are firmly connected as one unit, for good reason. This allows the grinding system including the motor to be mounted on a soft rubber ring in the housing without direct attachment to the housing. This means that the vibrations that occur during the grinding process are not directly transmitted to the housing and thus the noise development is reduced to a minimum.

Should readjustment be necessary after years of intensive use, this can be done relatively easily by adjusting the threaded rings on the grinding chamber. Opening the grinding chamber for cleaning purposes is also possible without much effort. While in the hawos mills the upper millstone is moved, in the Schnitzer Vario the motor is raised and lowered with the rotating millstone to adjust the distance to the upper millstone. You can get into the grinding chamber in one easy step by simply lifting off the bottom of the hopper. However, the Vario must be dismantled for readjustment.

Should readjustment be necessary after years of intensive use, this can be done relatively easily by adjusting the threaded rings on the grinding chamber. Opening the grinding chamber for cleaning purposes is also possible without much effort. While in the hawos mills the upper millstone is moved, in the Schnitzer Vario the motor is raised and lowered with the rotating millstone to adjust the distance to the upper millstone. You can get into the grinding chamber in one easy step by simply lifting off the bottom of the hopper. However, the Vario must be dismantled for readjustment.

In principle, the Mockmill is designed similarly to the hawos mills, as you can see in the video (under "Opening and cleaning the grinding chamber"). It is actually a successful combination of the KoMo and hawos adjustment system. Instead of turning the hopper, you move a lever.

Examples: Conveniently adjust the degree of fineness at the lever: Schnitzer Vario, Mockmill 100, hawos Oktagon 1

Examples: Conveniently adjust the degree of fineness at the lever: Schnitzer Vario, Mockmill 100, hawos Oktagon 1

Adjustment by turning the adjustment knob or wheel

The most convenient way of setting: one-hand operation. In the smaller Salzburger grain mills (e.g. Max-Spezial and Carina), an eccentric on the knob is used to raise and lower the motor with the rotating millstone via a lever in the mill housing. As the adjustment knob is on the right-hand side, this type is more suitable for right-handers. The adjustment can be made at the adjustment knob without disassembling the mill. You need a flat (thin) open-ended spanner for this, with which you loosen the fixing nut that protrudes only very slightly behind the adjustment knob. So it's not a big affair if the stones need to be readjusted after excessive or years of use. The mills from Wiederhold (e.g. Universalmuehle) stand out somewhat in terms of grinding technology. Grinding stones and motor are mounted horizontally here. The front, stationary millstone is pressed against the rear, rotating millstone with the adjusting screw. The front millstone can be removed in a few easy steps and used to access the grinding chamber for cleaning. Readjustment is also not necessary with this technique.

Examples: Most comfortable setting on the rotary knob: hawos Easy, Salzburger Max, Salzburger MT5

Examples: Most comfortable setting on the rotary knob: hawos Easy, Salzburger Max, Salzburger MT5

Advantages and disadvantages of the adjustment systems

The various adjustment systems have no influence whatsoever on the grinding result or the grinding speed and output.

Turning hopper: |

|

Slide lever: |

|

Turn button: |

Adjusting the grinding stones - not really an issue

In order for a mill to deliver the finest possible grinding results, the grinding stones must be positioned as parallel to each other as possible and have the smallest possible distance between them. In other words, they must be just close enough to each other so that they do not grind against each other and wear each other down. And this brings us to the subject of adjustment technology or adjustment systems. Depending on the adjustment or setting system, mills have to be readjusted to achieve the best results again. However, in normal household use for singles and families, readjustment is only necessary after decades, and only for mills with fixed "limited" adjustment possibilities (setting on the lever or knob) from fine to coarse.

Precision decisive for flour fineness

Precision decisive for flour fineness

Image: Pixabay / moritz320

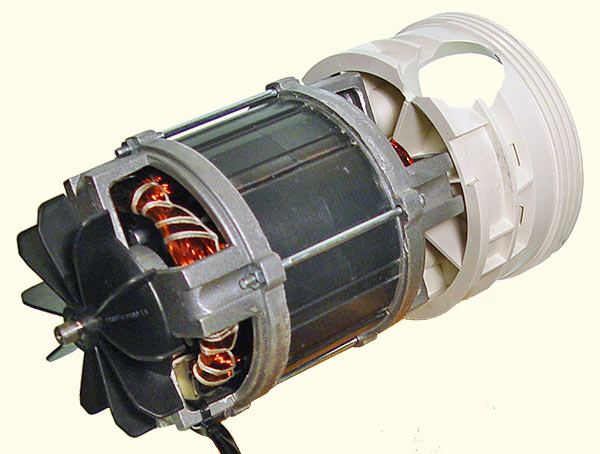

Engine and power

Stronger does not equal better! It depends on what you mainly want to grind. It is explained under the point "What grains can you grind". 250 watts power input is the minimum that can drive an electric stone mill, but it is definitely enough for common grains for baking. 360 watts and, more recently, 400 watts are standard (grain mills in the 100-gram class) and cover normal to high requirements. Some mills can also be used to grind maize. 600 watts (grain mills of the 200-gram class) are actually oversized for household use and can even be a disadvantage if you grind more than a handful of grains. When grinding larger quantities, the grinding stones of more powerful mills usually get warmer than those of weaker mills and end up so hot that oil escapes and smears the stones.

Die Drehzahlen bei den einzelnen Grain Milln sind nicht extra aufgeführt, weil sie bei allen ziemlich gleich sind, nämlich ca. 1300 Umdrehungen pro Minute. Eine Ausnahme macht hier die Elsaesser F100 mit 2850 U/min mit Kühlsystem.

The speeds for the individual grain mills are not listed separately because they are pretty much the same for all of them, namely approx. 1300 rpm. An exception is the Elsaesser F100 with 2850 rpm with cooling system.

Industrial engine of the flour mill Fidibus 21 with grinding chamber

Industrial engine of the flour mill Fidibus 21 with grinding chamber

Loudness

The manufacturers often also indicate the volume in decibels. I am omitting this here, however, because my impression was not always identical with the information. Unfortunately, the fact is that all grinders are very loud, but still more pleasant and quieter than blenders or stand mixers. To put it very simply, the noise level depends very much on the weight of the grinder, the construction and the shape of the grinder. An example is provided by the technically identical hawos mills Billy 100, Queen 100, Mill 1 and Oktagon 1. Same motor - same grinding stones - same grinding chamber - different housing shape > Oktagon 1 is the quietest. At Waldner, the Silence is the quietest electric mill.

Fineness of the ground wholemeal flour

Basically, you can say that all the mills here grind so finely that you can also bake wholemeal cakes with them. The milling results differ marginally. However, the texture of the flour is slightly different. The flour from mills with smoother grinding stones (granite and basalt-magnesite) feels a bit more velvety, in my impression. Grinding stone size and shape also play a role, the more grinding surface, the finer the flour.

Cream puffs made from freshly ground wholemeal spelt flour

Cream puffs made from freshly ground wholemeal spelt flour

Which grains can be milled?

In principle, all common types of grain can be ground, but very few can be ground at the finest level in large quantities, as most mills become hot and allow the oil to escape, which smears the grinding stones. Pay attention to the manufacturer's specifications as far as they provide information.

Hard grains such as maize, chickpeas or buckwheat require more power. Therefore, only mills with 550 watts or more are recommended for this purpose. But watch out: Popcorn maize tends to pull threads with corundum-ceramic millstones.

Rice is very hard, brittle and contains little oil. It can easily be ground into the finest rice flour. Because of its properties, it is also often used to clean the milling chamber. In the case of bagged rice or parboiled rice, it sometimes pulls threads like popcorn maize.

Widu mills are a big exception when it comes to grains. These can also grind oilseeds, spices, chopped nuts and almonds, hulled sunflower seeds and even coconut flakes and much more.

Grain spices such as pepper and cumin can usually also be ground, including coffee. For such cases, KoMo and Schnitzer have brought alternating grinders onto the mill market. But primarily for gluten-allergic families who want to grind both gluten-containing and gluten-free grains with just one mill.

You can grind all kinds of things, even pebbles with the Salzburger MT12 (video at Salzburger MT12). So you can definitely try out what can be ground. The stones can take a beating and the motor switches off if overloaded. But don't overdo it! I just want to take away your fear of trying new things. Understandably, I do not take any responsibility if you should manage to destroy a mill. If you have special wishes, ask the manufacturer or specialist dealer beforehand.

Grindability of grains and and granular spices by tasting in small quantities at different fineness levels.

Grindability of grains and and granular spices by tasting in small quantities at different fineness levels.

Image Pixabay / ulleo

Schnitzer Cerealos "Aroma Grinders" with interchangeable grinding mechanism

Grain Mills in practice

Handling and use

Most important rule: Always grind within sight!

Always stay nearby to your mill during the grinding process. Especially with larger quantities of critical cereals (those that contain more oil than wheat, spelt or rice), it often happens that the millstones run so hot if they are set too fine that the oil they contain escapes and smears the millstones. This has the undesirable consequence that the flour is no longer ejected. This is shown by the fact that the ejection stagnates and flour lumps are ejected intermittently until in the end nothing is ejected at all.

Immediately increase the coarseness if lumps are ejected!

If lumps are ejected, immediately adjust the mill to a coarser setting with the motor still running, until the flour is ejected evenly again. This will solve the problem. You do not need to disassemble and clean the mill. If, however, the mill continues to run unchanged until nothing more is ejected, it will run hot until the grinding stones finally block. The motor will then continue to whirr until it is switched off by the overload protection. Grinding stones and motor are not damaged yet, but you must act to avoid a major or even total loss. So open the grinding chamber immediately and clean it. If the ejector is clogged, unclog it. It takes work, but all is well again. If you simply leave the mill standing after it has jammed, the grinding stones will stick together so tightly that they can only be loosened again with a great deal of force.

Grinding with the first hawos grain mill 40 years ago

Grinding with the first hawos grain mill 40 years ago

Best possible degree of fineness can only be determined by trial and error!

Unfortunately, not everything can be ground at the finest level because of heating or because of the hardness of the grains. The finest possible setting can only be determined by trial and error. This also depends on the quantity. The less, the finer you can grind.

Do not fine-tune when stationary!

Grain Mills with grinding stone discs cannot be set finer when at a standstill, as the residual flour from the previous grinding process between the grinding stones prevents the setting from being narrower (finer). Coarser adjustment is possible both when the mill is at a standstill and when the motor is running.

Not all grains and seeds can be ground at the finest level! Wheat and spelt can be ground at the finest level.

Not all grains and seeds can be ground at the finest level! Wheat and spelt can be ground at the finest level.

First switch on the grain mill, then fill in the grains.

It sometimes happens that a mill does not start with the hopper already filled, especially with less than 500 watts power input. Therefore, first switch on the grain mill and fill the hopper with the ground material while the motor is running.

Grind large, hard grains twice

If you want chickpeas or maize to be ground very finely, grind in two passes. First at the coarsest setting, where the grains are only coarsely chopped, then at the finest setting. The grains must not be chopped too small in the first grinding pass, because the grains that are too small will then no longer enter the grinding chamber. However, you can help a little by hand by stirring the grains in the hopper and pushing them in.

Opening and cleaning the grinding chamber

With regular use, at least every 4-6 weeks, a mill never needs to be cleaned from the inside, provided the grinding stones are not smeared. If the mill is not used for a longer period of time, cleaning is recommended to prevent flour moths from settling in. For cleaning, it is sufficient to grind grain at medium to coarse setting and hold a hoover to the flour ejector so that all residual flour is also sucked out from under the millstone. Natural rice is even better suited than grain for this purpose, as its hardness makes it act like lubricating gel.

The grinding chambers of mills with adjustment by turning the hopper are the easiest to open. With other adjustment systems, no tools are usually needed either, but more handles are required.

Grinding chamber easy to open on the Vario with lever adjustment

Opening for cleaning the grinding stones in a KoMo mill

Opening and adjusting the grinder on the hawos Oktagon 1

Opening and adjusting the grinder on the Mockmill 100/200

Result

Grain Mill test: Recommendations

You now know what is important in a grain mill and can choose the best mill for your needs and tastes.

TOP-TEN electric grain mills

KoMo - KoMoMio

Fine flour for little money

Powerful 400W

Finely grinds chickpeas at the first grinding stage

Big hopper

Trendy colours selectable

Materials from renewable raw materials

TÜV GS certificated

UVP: 249,- €

KoMoMio at KoMoMio at ProducerMock - Mockmill LINO 100

Natural wood and HI-MACs© Natur Acrylstein™

Modern design

Large millstone

Large hopper

Produced in Germany

Also available with 600 watt motor as LINO 200

UVP: 459,- €

Mockmill LINO 100 manufacturer Mockmill LINO 100 atSalzburger - MAX SPEZIAL

Powerful natural stone mill

Granite grinding stones

Also grinds corn and chickpeas

Wooden grinding chamber

Most convenient setting on the rotary knob

Warranty mill 12 years

Warranty grindstones 24 years

UVP: ab 694,- €

MAX SPEZIAL manufacturerMock - Grain Mill Mockmill 200

Best price-performance ratio

Powerful 600W

Large millstone

Extendable setting range

Housing made from renewable raw materials

Produces in Germany

45 Grind Tests in video (Mockmill 100)

Even cheaper with 360 watt motor

UVP: 349,- €

Mockmill 200 at Mockmill 200 manufacturerKoMo - Grain Mill Fidibus 21

KoMo flagship - Success mill

Ideal for normal needs

Little space required

Hopper adjustment without locking screw

UVP: 299,- €

Fidibus 21 at Fidibus 21 manufacturerhawos - Grain Mill Oktagon 1

Very quiet

Very fine flour

Comfortable adjustment lever

Very large millstone

Solid construction

Timelessly beautiful shape

Also with 600 Watt as Okt.2

UVP: 449,- €

Oktagon 1 at Oktagon 1 manufacturerWIDU - Mod. III Universalmuehle

Unique all-rounder

Also grinds oilseeds, sunflower seeds, maize, etc.

Large millstone

Effective conical grinder

Big hopper (2,2kg)

Huge performance (300g/min)

Drawer (No flour dust!)

Produced in Germany

UVP: ab 562,- €

Universalmuehle at Universalmuehle manufacturerKoMo - Duett 100 und 200

Grain Mill with flaker

360W und 600W choosable

Proven technology from Fidibus Classic and FlocMan

Grind and crush simultaneously or one after the other

UVP ab: 719,- €

Duett 100 at Duett 200 at Duett 100 manufacturer Duett 200 manufacturerSchnitzer - Cerealo 125

Attractively priced alternative to the Fidibus Medium

125g/min with 360W motor

Housing made of robust beech plywood

Grinding chamber easy to open

UVP: 389,- €

Cerealo "natur" 125 at Cerealo "black" 125 at Cerealo 125 manufacturerElsaesser - F100

High grinding capacity

Dust-free due to collecting glass or bag

Effective cone grinder

Unique cooling system

Hopper expandable to 1600g

Steel grinding chamber

UVP: 998,- €

F100 bei getreidemuehlen.shop F100 manufacturer in D

About me / Author of the Grain Mill Test

The grain mill test from a mill dealer with practical experience

My name is Richard Kirschner. I am the author of the grain mill test and the operator of this website. My aim is to help and advise you in finding the ideal grain mill or the perfect flaker for you, or simply to give you tips on how to get started with wholefoods.

As enthusiastic users of wholefoods (cooking and baking with whole grains), my wife and I founded our online shop "top-getreidemuehlen.de" together in 1999. At that time, we only had the manufacturers hawos and König in our range. Over time, more and more manufacturers were added until we had all the well-known and relevant mill manufacturers in our mill range.

Through years of experience in testing the grain mills we sold and feedback from our customers, I can make specific recommendations depending on requirements and know the strengths and weaknesses of each grain mill. The new models since 2018 (KoMoMio and Mockmill mills) were provided to me by the manufacturers for testing after I quit the mill trade.

As a former master carpenter, I can also evaluate the material properties and the quality of workmanship from a professional point of view and find that there are no inferior grain mills from the German and Austrian manufacturers represented on my website.

Since 2018, I have been working as a freelance web developer and, among other things, run this website with the aim of being able to provide independent and fully comprehensive advice. The content created and testimonials are funded through affiliate programmes.

Do you have any questions about grain mills and flakers, or comments about the site itself? I look forward to your feedback via E-Mail

Roman and Viking hand mill at amazon

Roman and Viking hand mill at amazon Hand Flaker: Salzburger Master Flaker

Hand Flaker: Salzburger Master Flaker

more info

more info more info

more info more info

more info